We’re proud to introduce the launch of Drakewell’s new collision avoidance solution, Drakewell Anti-Collision. As with all of the features of Drakewell, we took a careful and measured approach to achieve a separation factor feature set with the highest level of usability, state of the art mathematics, and uncompromised reliability.

Drakewell users can now take advantage of advanced collision avoidance in the field, available as new surveys are entered without time-consuming imports or exports.

The Math

The math for calculating the separation factor is complex and critical. Error models, 3D math, and covariance matrices require high levels of expertise to properly understand and mathematical precision to get right.

While the software engineers at Drakewell are top-tier talent, the critical nature of this feature lead us to rely on the world’s leading experts in collision avoidance in order to implement the state of the art models and mathematics for Drakewell’s anti-collision feature set.

This expert team worked with the latest standards from the ISCWSA to create the mathematical model, ensuring the highest level of confidence in its accuracy.

This combines with Drakewell’s ease of use and shareability to create an industry leading and state of the art toolset for safe and accurate wellbore placement.

The Features

A New Screen

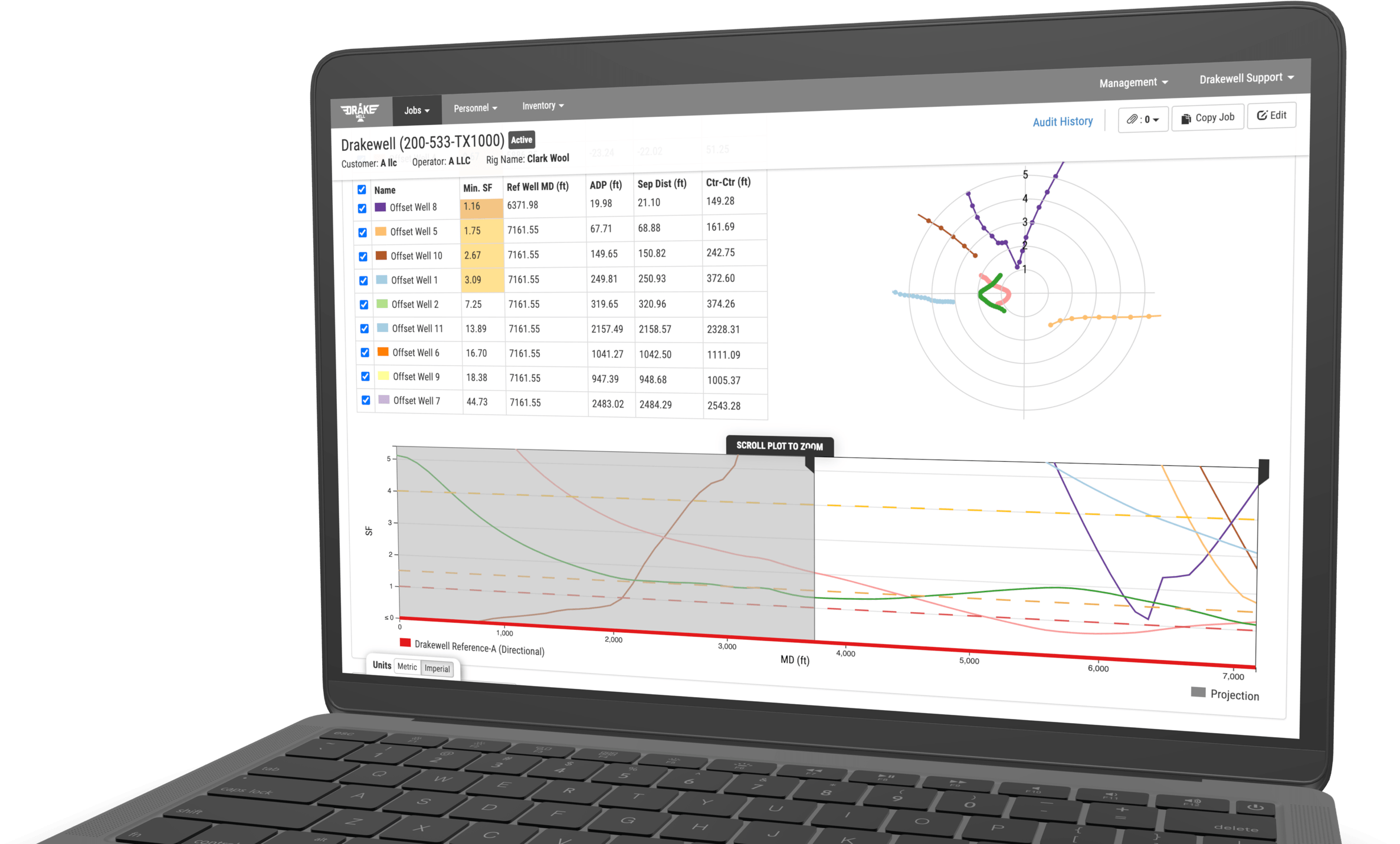

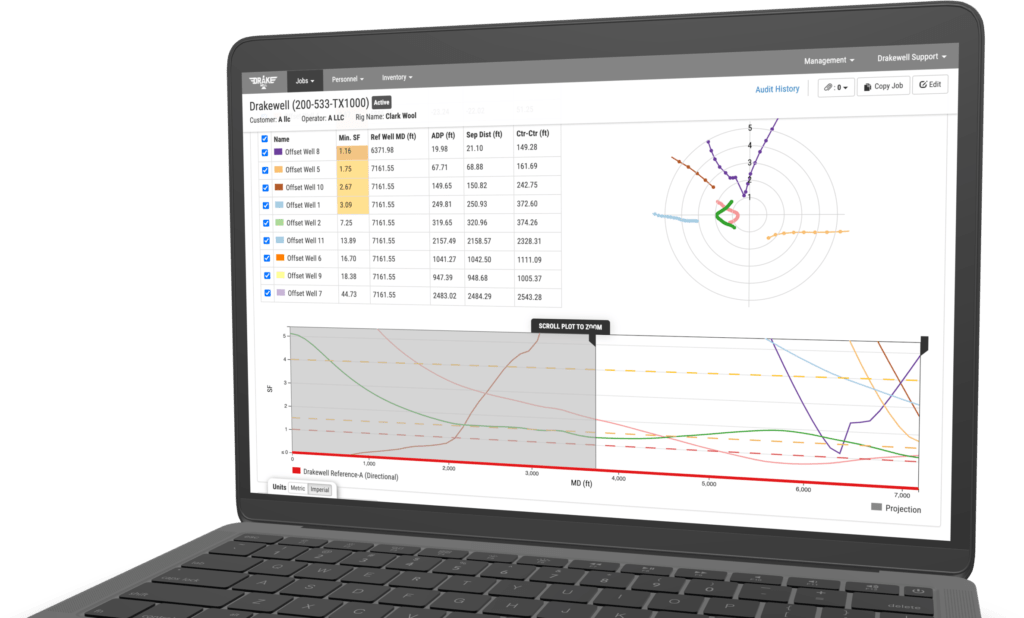

Our design study of collision avoidance led us down the path of creating a new screen within the job view in Drakewell specifically for that purpose.

This gives our customers a number of advantages:

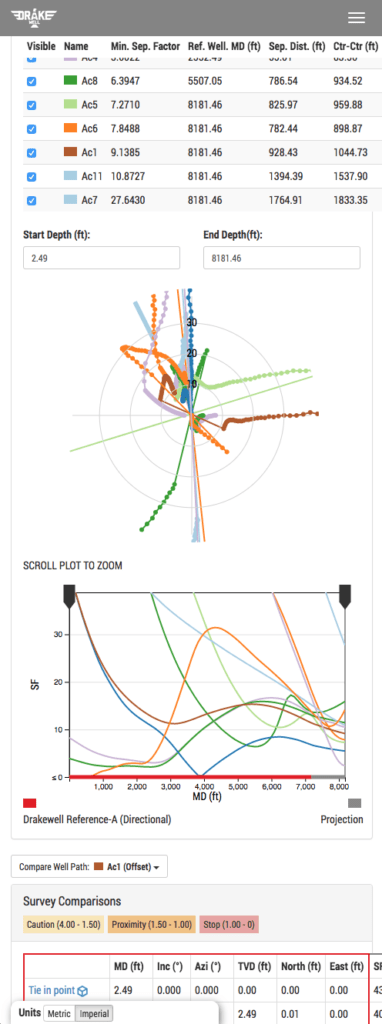

- Explore all paths at once – By creating a new screen we were able to optimize the design to allow users to see the relationship between the reference well and all other offset wells at the same time.

- New ways to view – The new visualization helps users see collision risks in powerful new ways. The ladder plots show upcoming risks, the toolface plot shows the toolface direction for any risks, and the risk table shows the highest risk locations along the upcoming projection.

- Shareable – The new screen adds additional shareability by allowing any user who has access to the job to see all of the risk factors quickly and from any device.

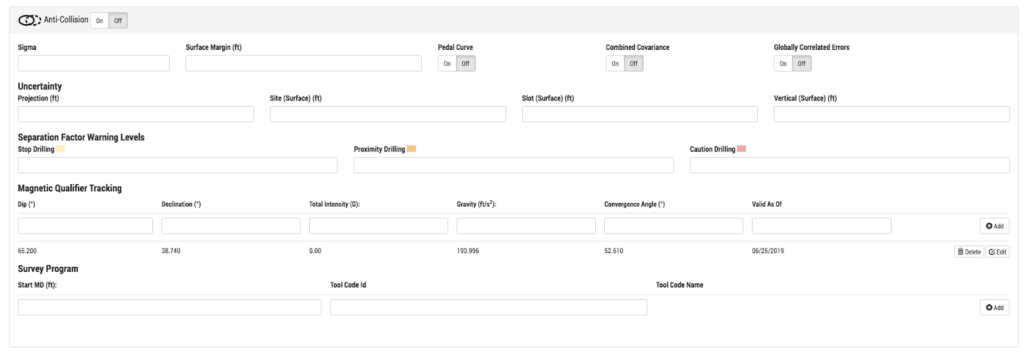

Setting Up A Job For Collision Avoidance

Collision avoidance calculations require additional information about the well. This includes more detailed magnetic qualifiers, site level uncertainty, tool code survey program, and max hole diameter. This information is needed for the reference well and any offset wells that require collision avoidance.

This information has been organized into two different places in Drakewell, and we have created a visual indicator for sections of information needed to run anti-collision calculations.

Job Level

The job level information can be accessed from the job edit screen. The information set here will apply to all directional, well plan, and test well paths created on the job. Some of these fields will be defaulted to industry standard values but can and should be changed as needed. We have also reorganized the job edit screen to make it easier to navigate.

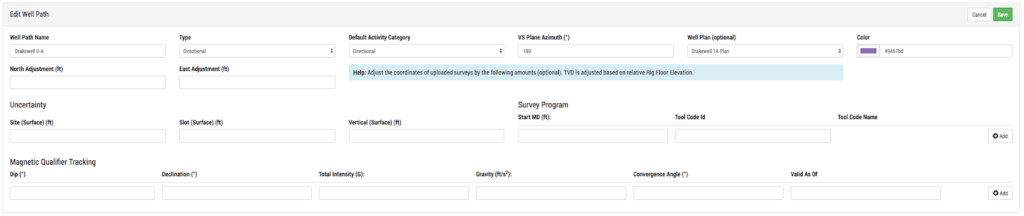

Offset Well Level

Each offset well requires a certain amount of information for anti-collision calculations. If a user chooses to run collision avoidance on a particular offset well, additional fields will be displayed and the necessary fields for the calculations will be required before that well path is saved. As on the job edit screen, sections required for anti-collision are indicated with the anti-collision icon.

The Usability

Present the worst first. The lessons learned from a study of the causes of the near nuclear disaster of Three Mile Island launched the modern User Experience industry. In his famous book on user interface and user experience, The Design of Everyday Things, Donald Norman emphasizes the necessity of helping users see the worst case information first.

In high precision or especially risky operations, clear, well presented, and meaningful information pointing to dangerous situations is the difference between loss of large amounts of money or even lives.

With Drakewell’s separation factor we followed these principles closely by creating a user interface to help drillers significantly reduce the risk factors involved in close proximity drilling through the following.

Critical Path First

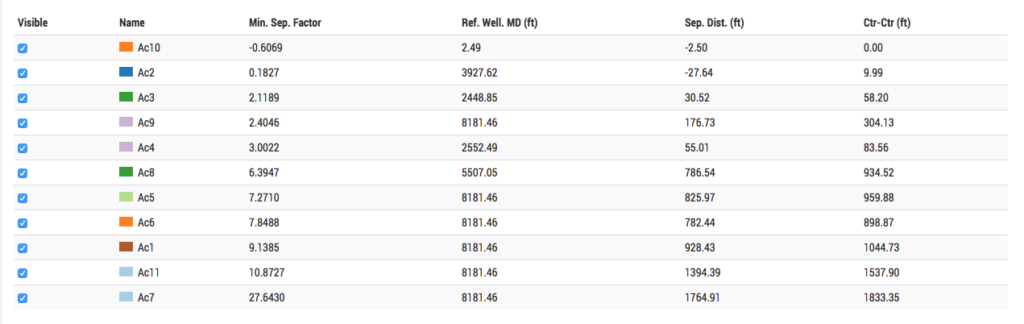

The very first information a driller sees on the Anti-collision screen (top left) are the most critical points in the planned, actual, or projected well path. We calculate this for all offset wells at once and sort by the worst first.

Increasing Granularity

With the critical information highlighted at the top, as the user scrolls down the screen an increasing amount of granularity is presented in the following ways:

- Users can zoom into trouble spots on the ladder plot and the toolface plot.

- The ladder and toolface plot can be filtered by measured depth.

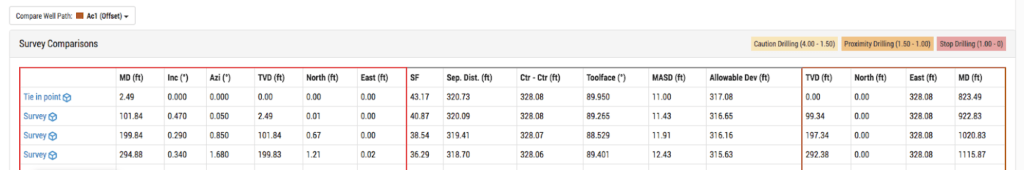

- Below the plots, the detail increases allowing a user to see the entire reference well path compared to one offset well path at a time. Caution, Proximity, and Stop Drilling parameters are highlighted so that a user can quickly see the risk areas in detail.

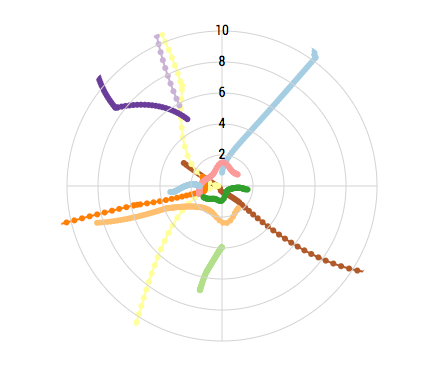

Toolface Plot

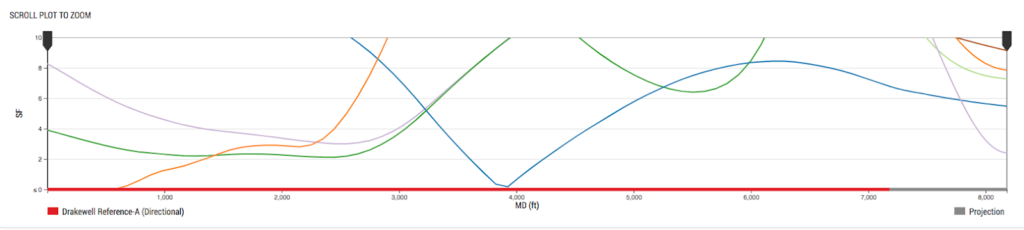

Ladder Plot

Offset Well Details Table

To see all of the details, a user can select each offset well in the dropdown box below the graphs. The detailed collision risk information for that entire well path related to the reference well path is displayed including colors indicating risk ranges.

Shareability and Distributed Information

Drakewell is designed from the ground up to allow information to be easily shared to everyone involved. With Drakewell you don’t need to wait for emails, texts, or phone calls to see what’s happening on the well site; instead, it’s available in real time from any computer or mobile device.

Clear Visualization

Understanding the risk factors across many offset wells for an entire wellbore can become a nightmare of information overload. Presenting this information in 3D can often cause visual crowding which will overwhelm a user and cause critical information to be hidden. To solve this problem, our UI/UX team spent dozens of hours creating a clear picture of risk, that’s easy to understand.

The ladder plot shows the user the separation factor for an entire wellbore. Users’ can zoom in and out of the plot as well as highlight certain measured depth ranges.

The toolface plot shows a user separation factor related to the toolface allowing a user to not only see the risks but also understand the direction to avoid.

Both the ladder plot and the toolface plot include the wellbore drilled points and projected points for the entire well plan.

What’s Next?

Beta Launch

After significant effort to make sure this feature set is up to Drakewell standards we’re proud to launch it into our customer’s hands. We will keep this feature set in Beta for a period of time, not because of any lack of confidence, but instead to encourage our customers and users to give us feedback.

As with all of our features, we are committed to making our collision avoidance features best of breed in the industry and we’re excited to hear from our users.

Additional User Interface

There are a number of additional user interface features we have planned after this initial launch. We will combine this with feedback from users to continue to improve the feature set.

Shareability

Collision risks are among the most important information for everyone involved in drilling a wellbore. To that point and many other points of important information, we are working towards a whole new way to share information from Drakewell, securely and reliably.

Consistent Updates

Tool codes change, math is improved, and new ISCWSA standards are approved. As these things happen we will continue to update the collision avoidance feature set to be state of the art.

References

The following references are industry best practice standards for collision avoidance:

Introduction to Wellbore Positioning by Angus Jamieson

Collision Avoidance Lexicon by the ISCWSA Collision Avoidance Work Group