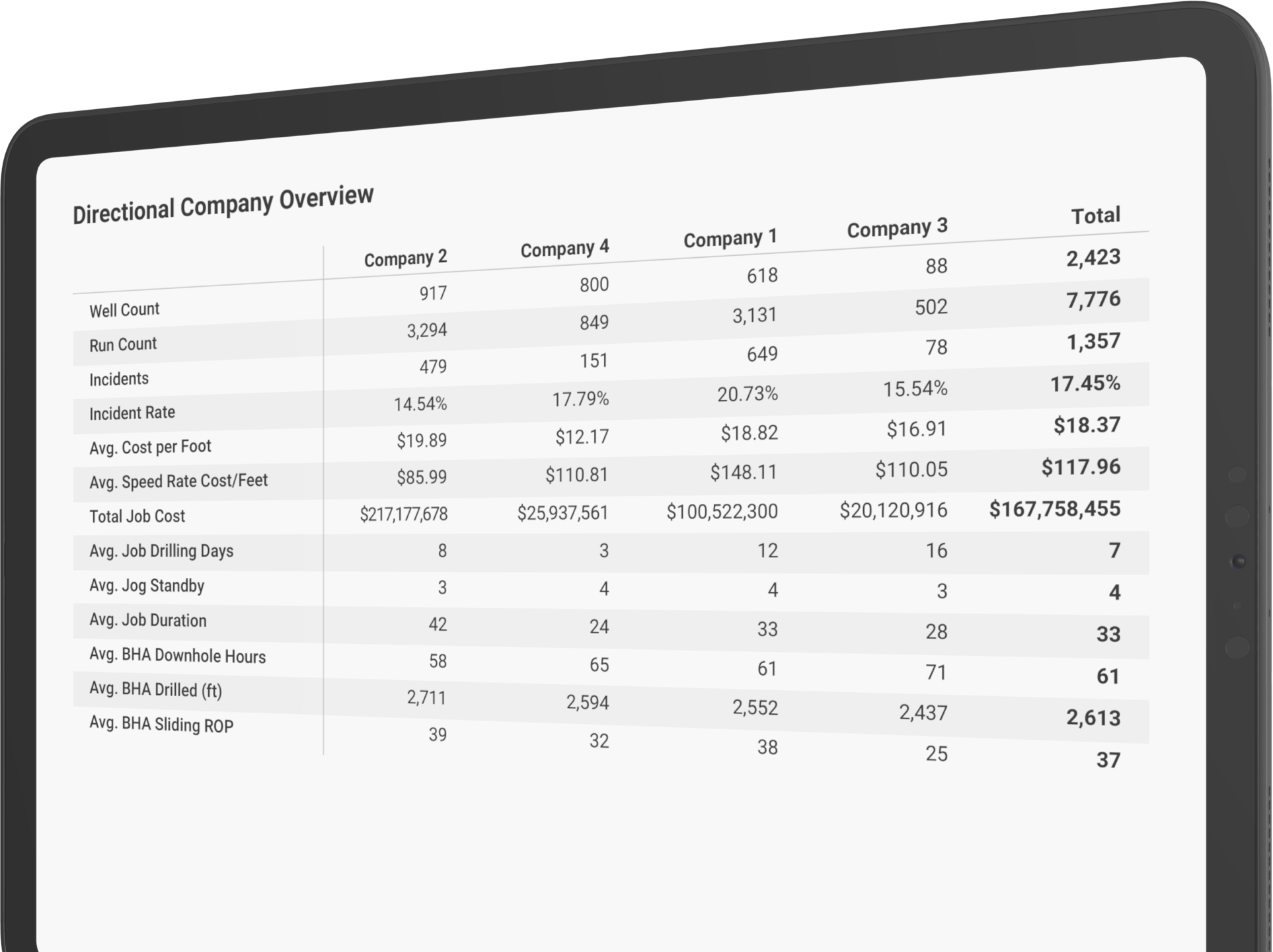

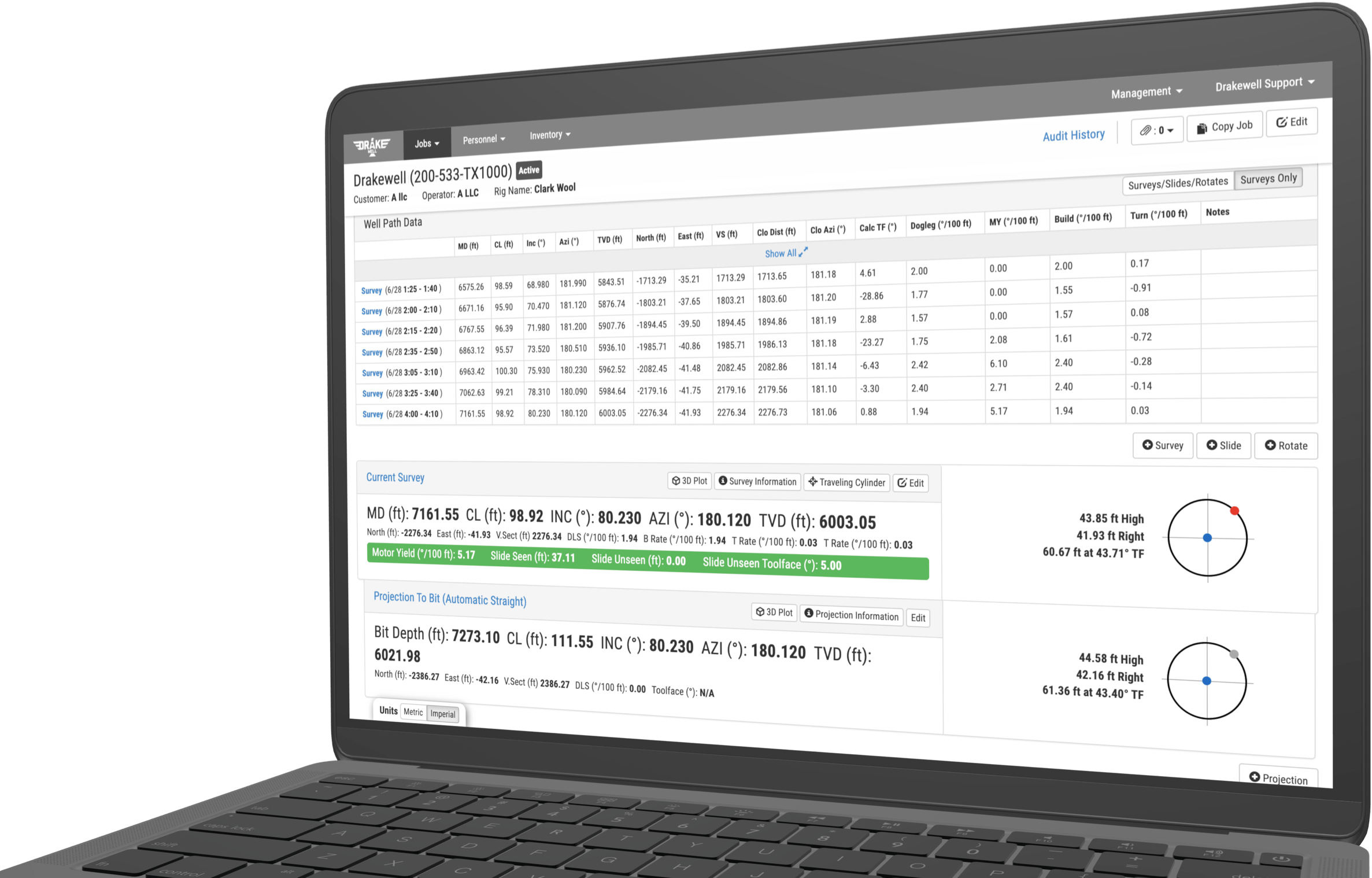

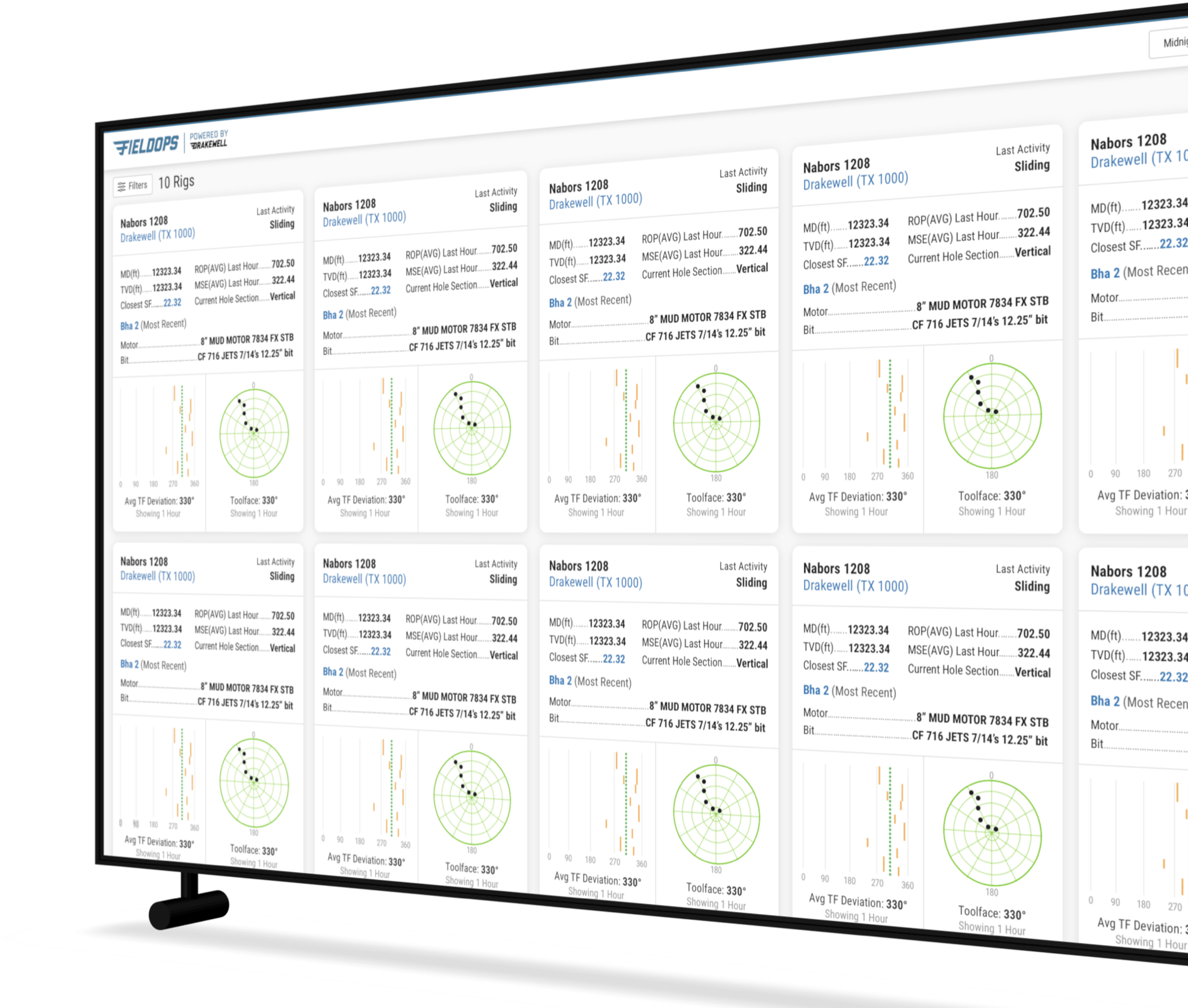

Designed for Operators.

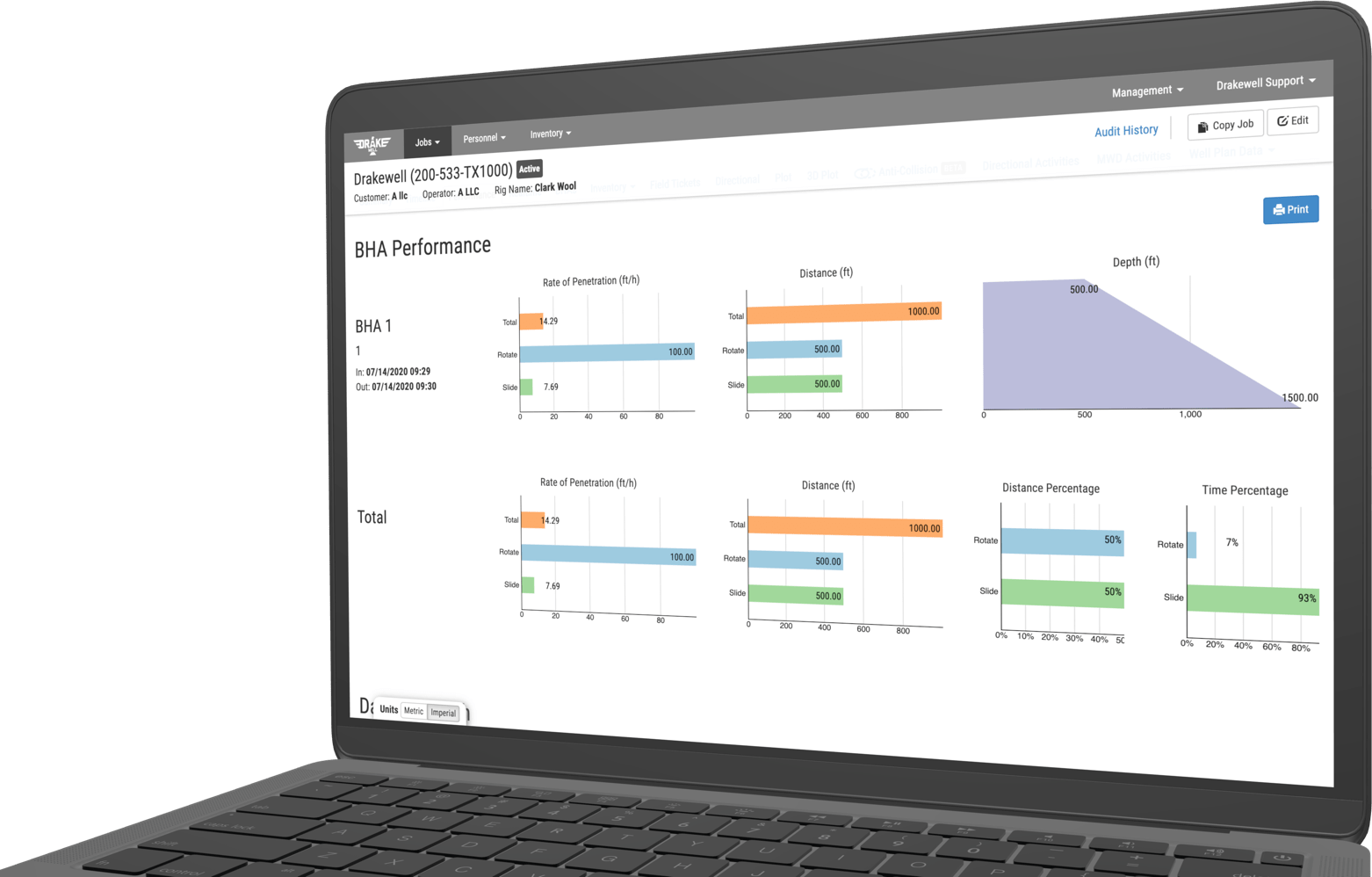

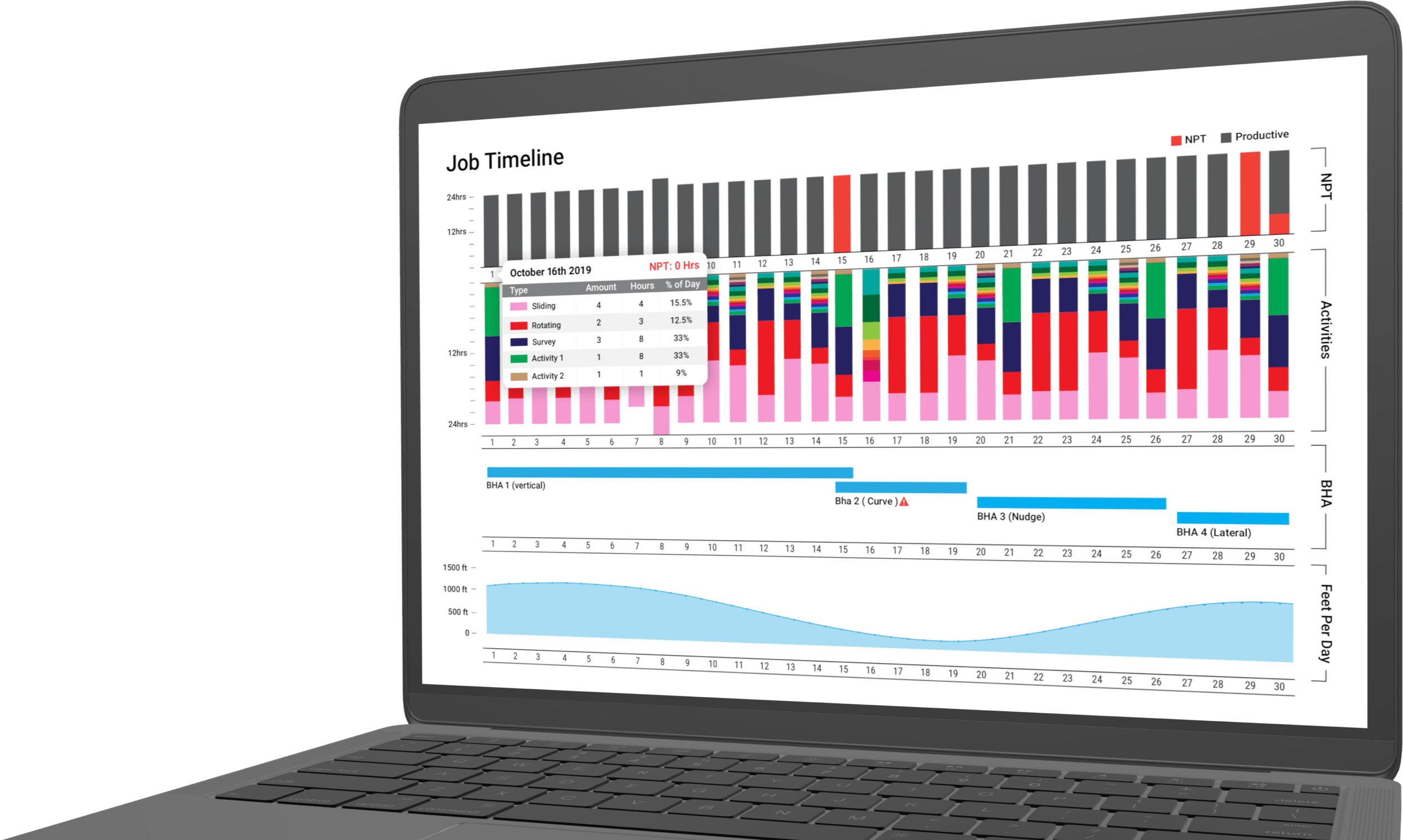

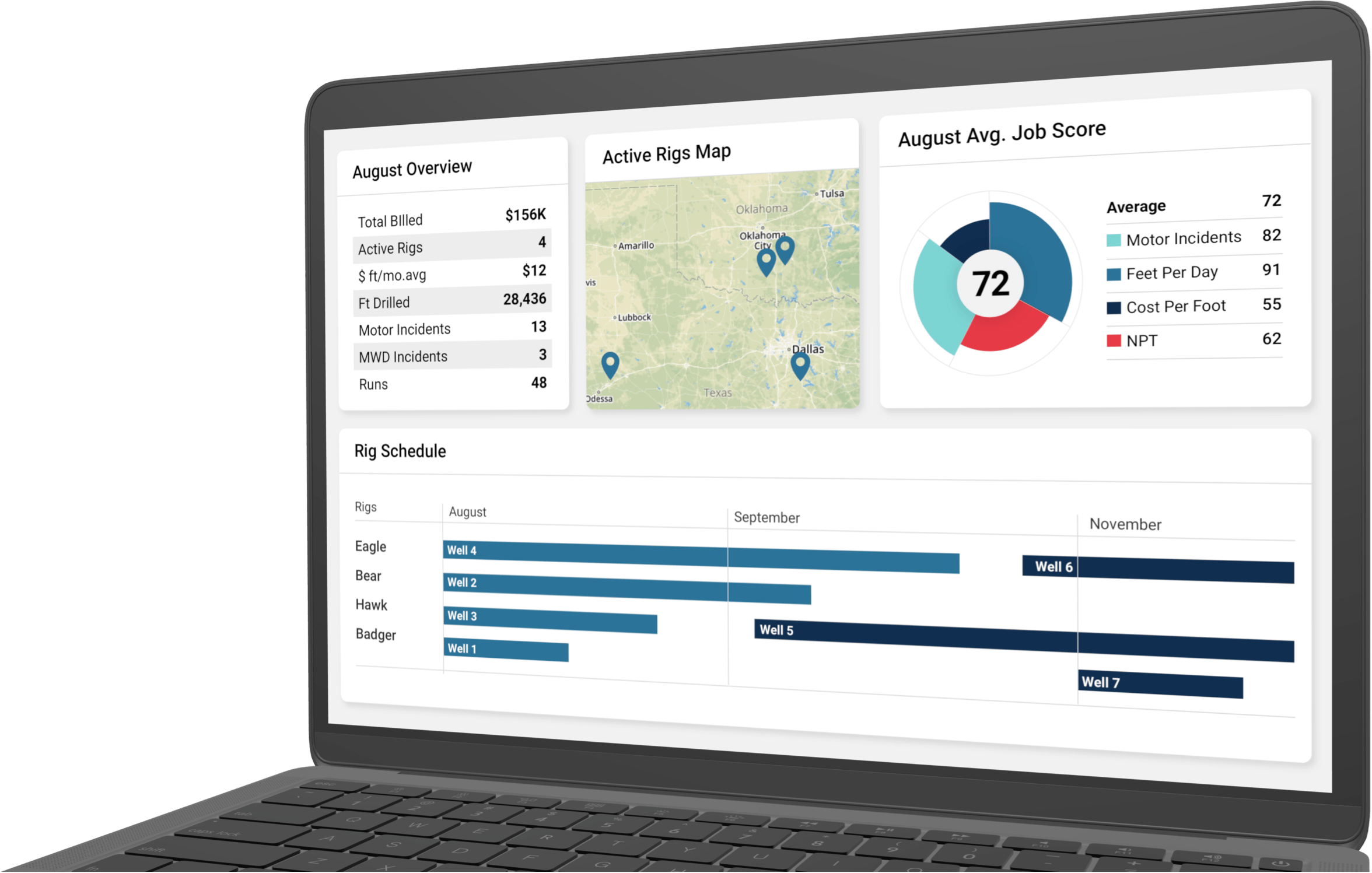

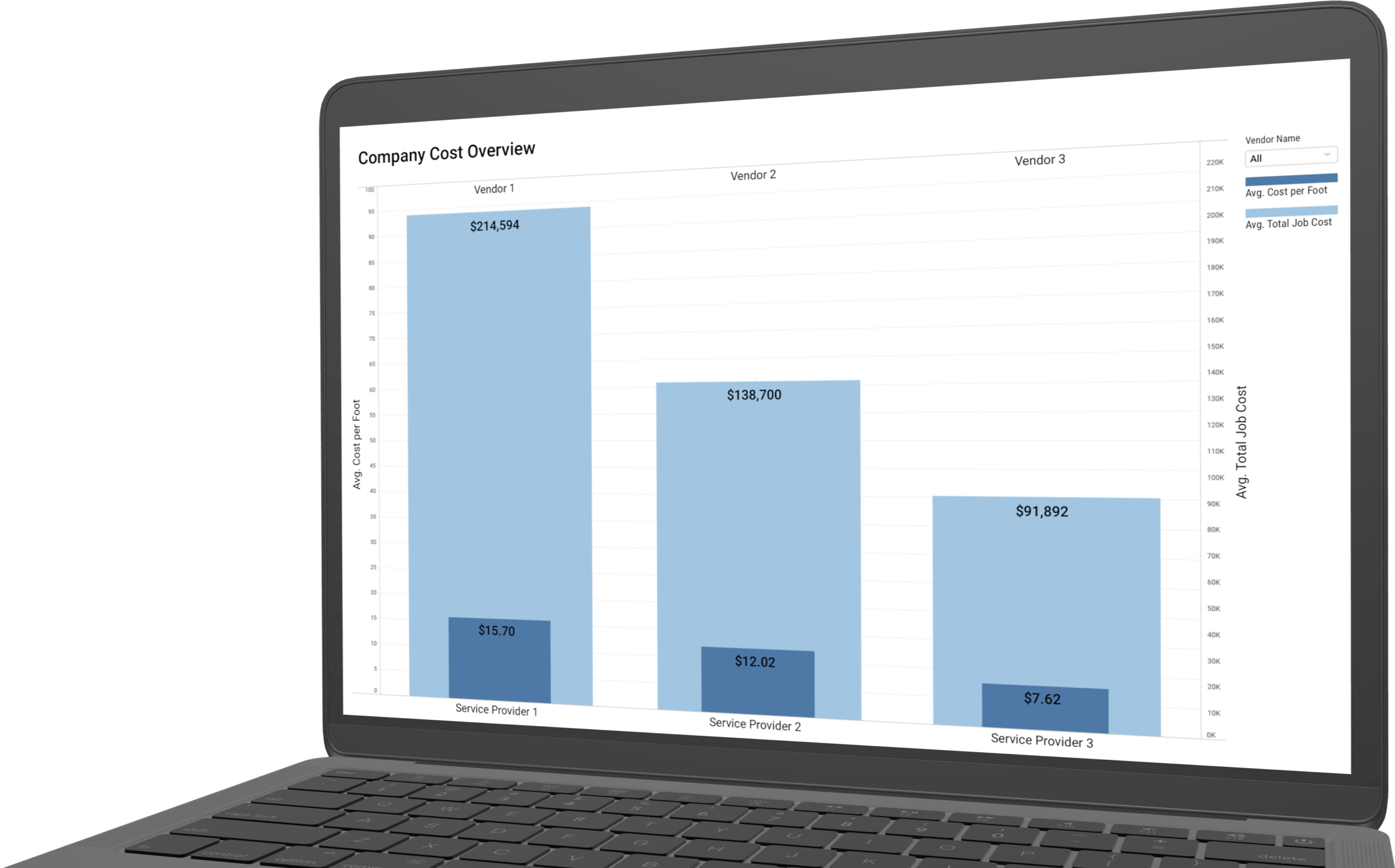

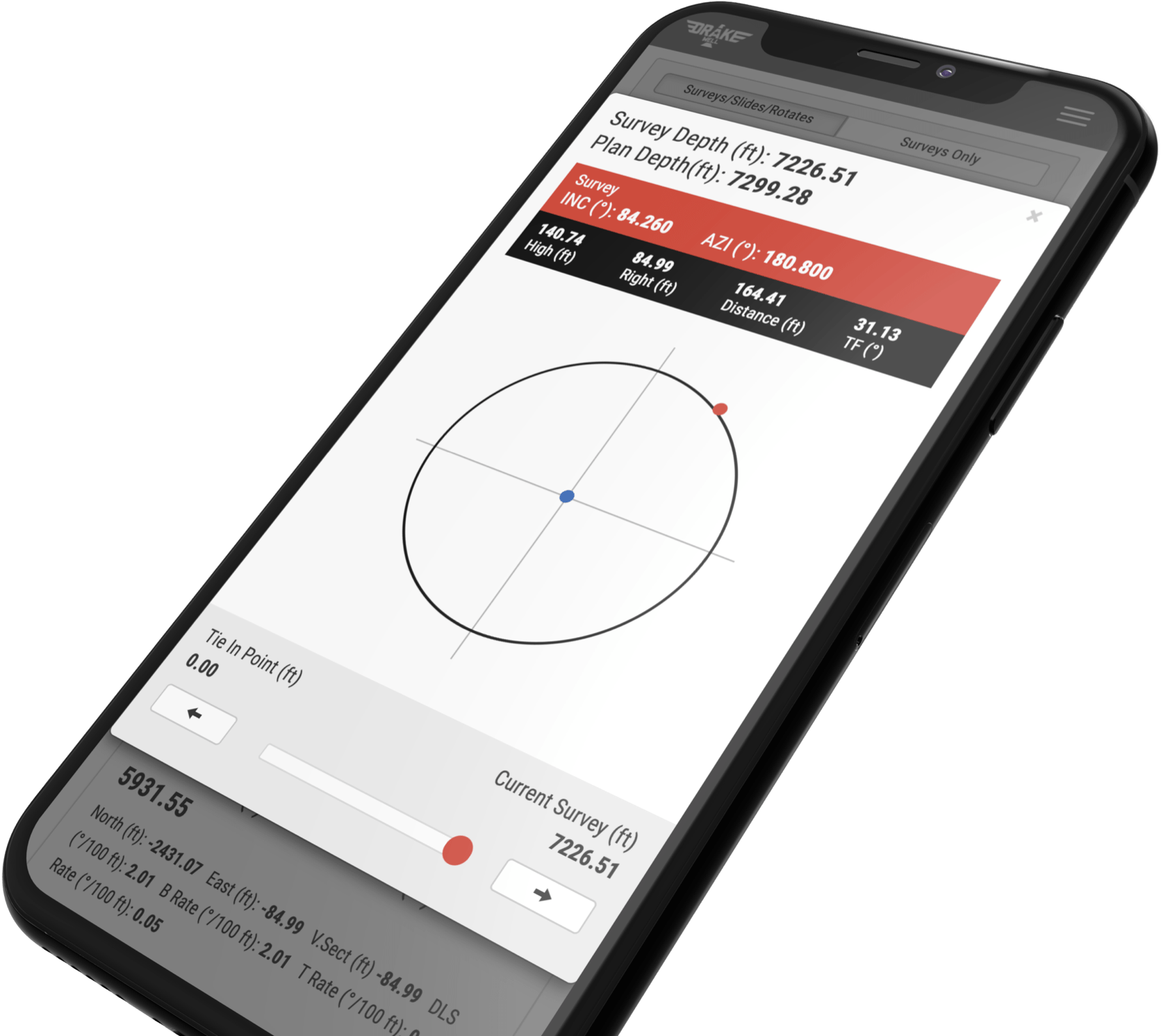

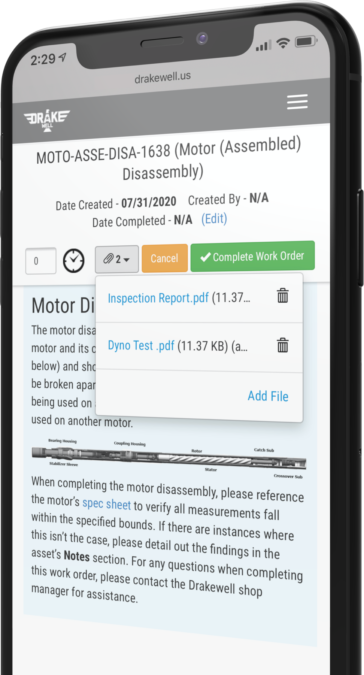

A scalable and sustainable way to get consistent, clean data from disparate service providers.

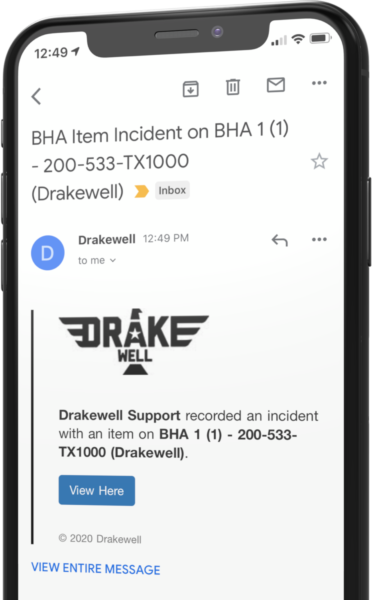

Report Notifications

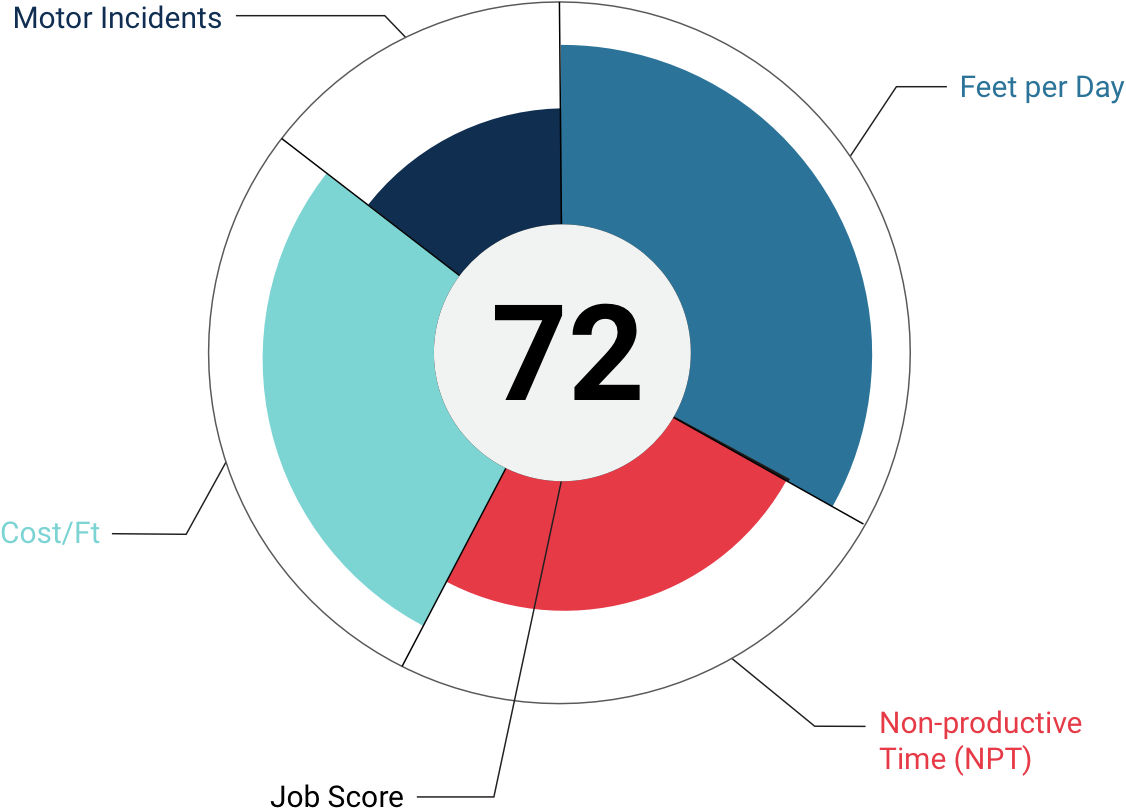

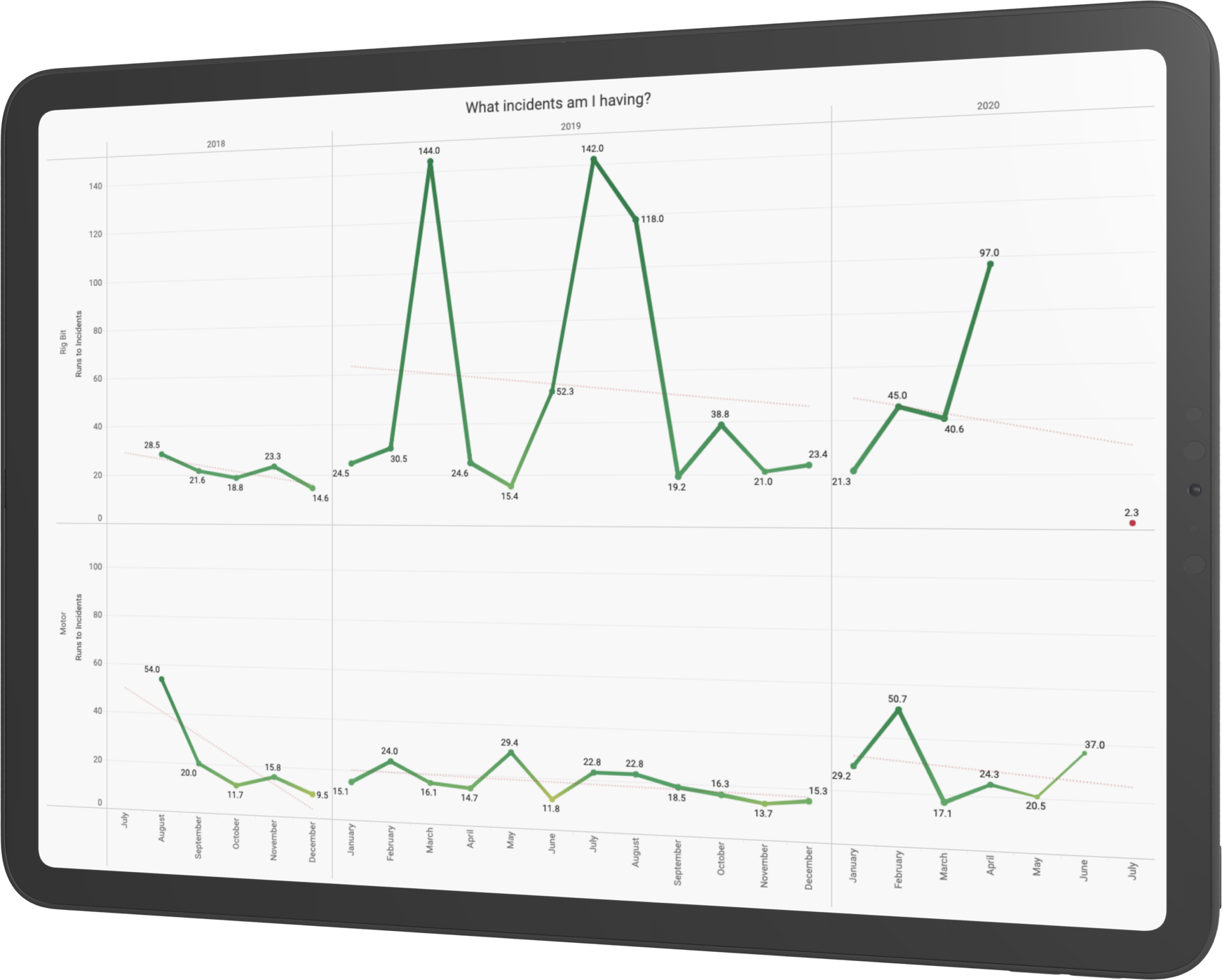

Stay informed and analyze incidents and root causes for failures help reduce costs in the near term and harness lessons learned over time.

In depth blogs about new features